By Alisson Pacheco Ramos, BA in Management & Finance at Audencia Business School

Should we abandon the Just-in-Time system? This bold question is becoming increasingly relevant today since, as the name implies, this system depends on a tight logistics flow that can only operate efficiently in a predictable and stable environment.

When the Just-in-Time (or JIT) system was originally created, it was made for this exact type of environment: in mid-20th century Japan, an engineer working at Toyota came up JIT as a method of reducing what he called “waste” (which includes unnecessary time, resources and materials) in the producer-supplier ecosystem around the Toyota factories. At that time, JIT was designed for a smaller scale, where factories and suppliers are located near each other, eliminating transit time as well.

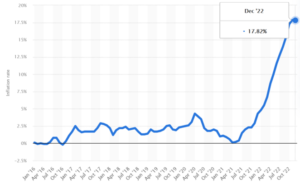

However, the JIT concept was later extended to the global economy, and favorable conditions allowed this system to continue functioning even as transit times and distances were greatly extended. JIT is now defined by the University of Cambridge as a management philosophy in which production must meet the exact needs of the customer, at the right time, quality, and quantity, on all ends of the logistical chain. Unfortunately, our current times are full of uncertainties and unpredictable events happening simultaneously. Geopolitical tensions between the United States and China, the Covid-19 pandemic, and the consequences of climate change have all taken a toll on the JIT system. As shipping schedules have become unreliable during the pandemic, certain products experienced mass shortages (such as semiconductors). This became further exacerbated when the war broke out in Ukraine, making gas and oil prices skyrocket in Europe and inflating food prices greatly (such as seen below).

Source: 2023, Nils-Gerrit Wunsch, “Inflation rate for food in the European Union (EU) from January 2016 to December 2022”

In light of these challenges, some question whether the JIT system is still viable in our modern, unpredictable world. While it has certainly proven to be an effective method of reducing costs and streamlining production efficiently in stable times, it may not be able to withstand the level of volatility and uncertainty we are experiencing today.

The first solution: abandon JIT altogether for another model

Undoubtedly, the implementation of JIT has enabled companies to drastically reduce their costs, thereby driving down prices for consumers and providing easy access to cheap products in large quantities for the middle class over the past few decades. However, this achievement has come at a cost. Critics argue that our JIT-based society has exacerbated the proliferation of low-wage, precarious jobs, leaving overworked employees with little job security, deepening an ever-growing economic inequality.

As mentioned earlier, the JIT model is being increasingly questioned in light of current events It has become apparent that the JIT-based system is not sufficiently reliable or resilient to provide for the needs of our society or our increasingly globalized civilization, particularly given the acceleration of the effects of climate change that we are currently witnessing.

One solution could be to abandon JIT altogether in most companies, even though this would likely result in higher costs. However, this could also lead to more stable prices in the long run, as everything would be better calculated in advance to prevent shortages..

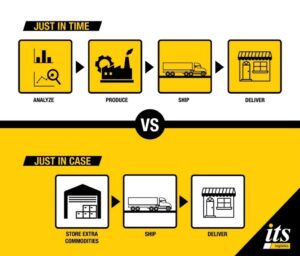

Still, what would replace the JIT model? The most common alternative is the Just-In-Case, or JIC model, which involves building buffers along the supply chain to maintain large inventories and reduce the chance of running out of stock. This approach was adopted by companies to deal with the unpredictability of the pandemic.

Here is an illustration that shows the difference between JIT and JIC:

Source: 2023, ITS Logistics, “Inventory Management: Just in Time Versus Just in Case”

While the JIC system has proved to be an expensive alternative to JIT that can fulfill basic consumer needs during unpredictable times (where customer demand is hard to anticipate), maintaining this kind of supply chain is becoming increasingly unrealistic due to the high costs involved (mostly due to all the additional costs of maintaining large inventories). These costs are later passed on to the end consumer, worsening inflation.

This means JIC is not really an alternative, rather, it is a supplementary solution that companies can adopt depending on their needs, strategy, and environment (nature of the product and suppliers), and it cannot be extended to our globalized economy. Nevertheless, in certain regions around the world where JIT does not work due to insufficient infrastructure, JIC-based solutions are being investigated for implementation.

Another solution: digitize supply chains

Another possible solution would be the digitalization of the supply chain – this has the potential to revolutionize the way we manage our resources and supply networks. By centralizing all supply chain data and processes through dedicated software, companies can make more informed decisions, have greater control over their operations, and respond more rapidly to sudden changes.

In practice, supply chain digitalization means that all useful information from the entire supply chain, including external sources like socioeconomic data, is collected in a centralized database. With this approach, companies can eliminate the need for manual data entry and invoice processing, streamlining their operations and reducing the potential for human error.

This makes the supply chain more efficient and more resilient to unexpected disruptions, thanks to a more agile, flexible approach; this is becoming increasingly important in our current global climate.

Nonetheless, this kind of approach involves a high level of collaboration and interconnectedness in order to be implemented, as companies will have to have access to as much data as possible, data that in reality will come at a certain cost (financial, but as well environmental). Besides, recently some researchers observed that it is still unclear which digital tools impact supply chain resilience best.

A more promising solution: revamp the JIT supply chain

This means a combination of adding resilience to some JIT segments by creating a buffer – not unlike what JIC is based on – and the use of digital technologies to make the JIT network even more resilient.

This way, companies will still be able to reduce most of their costs since they will not abandon their JIT system in itself. Instead, they will make it evolve to be better adapted to our unpredictable environment.

The Harvard Business Review (HBR) has most notably outlined here that companies don’t have to keep their whole value chain JIT-based. Instead, they must divide their JIT Network into what the HBR calls “JIT supply chain segments.”

These segments will be favorable to a JIT system, meaning they have predictable and stable demand and proximity between actors, similar to when the JIT system was originally implemented by Toyota. Then, to ensure a resilient supply chain, these JIT supply chain segments can be interconnected through buffers that incorporate similar methods as the Just-In-Case (JIC) system, such as holding extra inventory, increasing storage capacity, or establishing backup suppliers. Having a single buffer back up two distinct JIT segments can provide protection for JIT segments that rely on less cooperative or more distant suppliers. Additionally, the buffer can be accordingly expanded to accommodate any potential disruptions in the supply chain (such as unreliable suppliers).

As previously mentioned, combining the JIT supply chain segments with digital technologies can enhance supply chain security. However, the HBR suggests further utilizing emerging digital technologies such as AI, the Internet of Things (IoT), and blockchain to further increase supply chain resilience. For instance, certain companies already use IoT technologies like RFID tags to improve visibility and traceability throughout the supply chain.

Source: 2023, Zetes, “RFID in Supply Chain.” *RTI’s: returnable transport items

And the ultimate solution the HBR highlights is the use of 3D printing to manufacture on demand what the company currently needs, such as spare parts. It would also be conceivable to pool these printers, much like FabLabs (Fabrication Labs) that already exist and are available to the general public, but instead make a B2B service in which 3D printers would be made available to companies –as this already exists as well to some degree, we might be on the path to a more sustainable and resilient supply chain.

Alisson Pacheco Ramos

Alisson Pacheco Ramos is a Peruvian student pursuing a Master's degree in Management and finance at Audencia Business School in Nantes, France. She is passionate about Finance and Strategy Consulting. Her motivation for social innovation, responsible business, and sustainable development as a strategy drives her to always surpass herself and anticipate the future, transforming large-scale, high-impact businesses. Her ability to communicate effectively in multiple languages is a valuable asset, she combines her excellent analytical skills in financial services, network excellence, digital, and cost analysis with knowledge of Law, Accounting, digital marketing, and renewable energy to advocate for impactful solutions firmly rooted in scientific evidence, spanning Business, Markets, and Sustainable Finance.

I gotta favorite this web site it seems handy very helpful