By Anjali Tohani, Analyst at Warwick Commercial Awareness Society

By Anjali Tohani, Analyst at Warwick Commercial Awareness Society

Ever since the first closures of automotive production lines during the first quarter of 2021, the semiconductor industry found itself in an unprecedented situation. The industry went from being the key driver in technological advancements, aiding many manufacturing processes in their aim to become more efficient and create higher quality electrical products, to being an industry that worried investors and firms all over the world.

Why are these tiny chips so important?

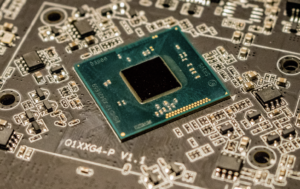

Semiconductors have allowed us to live in a world as technologically advanced as we see it today. The concept of semiconductors paved the way for the production of microchips which have ultimately led to the digital revolutions seen today. Semiconductor chips are the basis of almost all electronic devices, from the phone, laptop, or tablet you are reading this article on, to the electronic vehicles which have become increasingly popular in the last decade. Without these chips, we would still be in the era of old and bulky vintage computers, which further evidences how the semiconductor industry can be thought of as the pinnacle of technological advancement. In 2010 the average car used US$300 worth of microchips, and by the end of 2022, this number is estimated to increase to US$500 as automobiles become ever more digitalised. Ultimately, this has led to increased pressure due to the rising demand for the semiconductor industry.

Causes and consequences of the chip shortage

There are several reasons which explain how the global semiconductor shortage arose and among all of them, the impact of COVID 19 on the various industries is a recurring theme.

In the first half of 2020, the auto industry saw a considerable drop in demand as lockdowns were implemented around the world. Even when sales did begin to pick up in the second half of the year, negative and uncertain economic sentiment led auto manufacturers to lower their own sales predictions, causing them to underestimate the inventory they needed and therefore decreased their demand for semiconductors.

However, at the same time, demand for these chips was increasing within other industries. Remote working became the norm for many and so the need for laptops, mobile phones, and other accessories, such as cloud storage and software drives increased. Even as the pandemic moves closer to an epidemic, these levels of demand are yet to return to pre-pandemic levels. In fact, the pandemic caused PC sales to increase by over 50% year on year in early 2021. Chip manufacturers shifted production from automobile chips to chips compatible with home electronic devices. Thus, when semiconductor demand from the auto sector rose in the latter part of 2020, the semiconductor industry, already under pressure from other sectors, did not have the capacity to increase chip supply. For this reason, the automotive industry became one of the first to experience bottleneck supply as the shortage haltered production. This has impacted all auto manufacturers, including the biggest firms such as General Motors which saw sales plummet by 30% in 3Q21, Toyota which saw its 3Q21 profits fall by 21%, and Ford, which recently laid out plans to cut or reduce production in eight of its factories in the US, Mexico, and Canada .

However, this shortage has not only affected the auto manufacturing industry. As aforementioned, semiconductors are the backbone of nearly all electronic devices, turning their lack of availability into big crises for many firms which not only produce electronic goods, but also those which benefit from them in their manufacturing processes. Even Apple, the nearly USD$3tn company and the world’s biggest buyer of semiconductors (USD$58bn annually) was forced to delay its launch of the iPhone 13 in 2021. For the same reasons, Amazon also revealed in its third-quarter earnings report that it missed its revenue estimates.

What’s next for the chip industry?

Chipmakers are trying hard to keep up with the demand, and in 2021 we saw the three biggest chipmakers announce cumulative capital expenditures of over USD$60bn, with this number set to increase during this year. Additionally, governments have pledged themselves to help the local industries since as of 2020, 81% of semiconductor manufacturing was based in Taiwan or South Korea. Now China, the USA, and the EU are all fully committed to increasing their countries’ production of chips, in an attempt to decrease international dependence and prevent future supply chain disruption while simultaneously occupying this market gap and using this as an opportunity for profit not only through arbitrage but also due to the international shortage and hence higher bargaining power.

The debate over when the semiconductor shortage is likely to end continues, with some estimates saying we should see it ease by the second half of 2022, whilst others suggest the easing will not be observed until at least 2023. It will be interesting to see how quickly global production will be able to recover and how firms and governments will prevent future disruption to the chip industry, especially given we are in a period of ever-increasing dependence on technology. Overall, however, it is clear that the shortage of semiconductors has severely disrupted production, supply, and profits all over the world.